limitations of hardness test|hardness testing process : convenience store In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different . The SD 660 series of fully automatic steam sterilizers provides large-volume sterilization without compromising sterilizing speed. This combination provides high throughput capacity demanded by modern CSSD’s, TSU’s, laboratories, .

{plog:ftitle_list}

Otra forma de indicadores de autoclave son los indicadores biológicos. Éstas contienen una población estandarizada de esporas bacterianas resistentes, como Geobacillus .Vulcanizing autoclaves use live internal steam, a mix of live steam and hot air, or hot-air only. Vulcanizing autoclaves are used to cure tires, hoses, and many other products that might not lend themselves to a standard press-based .

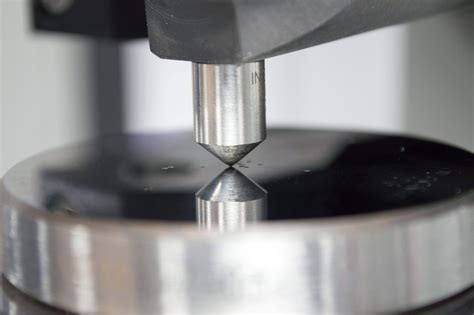

Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the . In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different . Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the sample to .In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.

Traditional hardness measurement is only applicable to large-sized samples, not only due to limitations of the measuring instrument, but also because the residual indentation cannot accurately reflect the true hardness of the sample at the micro- and nano-scales.There are different reasons for this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, and the Rockwell scale is a commonly accepted value when purchasing products. Industrial Application. Surface Roughness.

In the manufacturing industry, we are measuring the hardness of the metal by various hardness tests and one of them is the Brinell Hardness Test. In this article, we will see its performing methods, advantages, disadvantages/limitations, and applications.The Brinell Hardness Tester, a widely used method for assessing material hardness, offers several advantages and limitations that are important to consider when performing hardness testing. Understanding both the strengths and weaknesses of the Brinell Hardness Test is crucial for obtaining accurate and reliable hardness measurements.

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Request Quote. The Brinell hardness test is a commonly used hardness testing method that measures the hardness of materials. It does so by pressing a hard ball indenter into the surface of the material under a specified load and calculating the hardness based on the size of the indentation. Brinell hardness testing has its limitations, however, including the need to use a selection of different-sized indenters depending upon the material under test and, sometimes, it’s not suitable for testing very small components.

This article describes the principal methods for macroindentation hardness testing by the Brinell, Vickers, and Rockwell methods. For each method, the test types and indenters, scale limitations, testing machines, calibration, indenter selection and geometry, load selection and impression size, testing methodology, and testing of specific . Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the sample to .In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.

Traditional hardness measurement is only applicable to large-sized samples, not only due to limitations of the measuring instrument, but also because the residual indentation cannot accurately reflect the true hardness of the sample at the micro- and nano-scales.There are different reasons for this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, and the Rockwell scale is a commonly accepted value when purchasing products. Industrial Application. Surface Roughness.

In the manufacturing industry, we are measuring the hardness of the metal by various hardness tests and one of them is the Brinell Hardness Test. In this article, we will see its performing methods, advantages, disadvantages/limitations, and applications.

The Brinell Hardness Tester, a widely used method for assessing material hardness, offers several advantages and limitations that are important to consider when performing hardness testing. Understanding both the strengths and weaknesses of the Brinell Hardness Test is crucial for obtaining accurate and reliable hardness measurements.Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Request Quote. The Brinell hardness test is a commonly used hardness testing method that measures the hardness of materials. It does so by pressing a hard ball indenter into the surface of the material under a specified load and calculating the hardness based on the size of the indentation.

what is a hardness test

Brinell hardness testing has its limitations, however, including the need to use a selection of different-sized indenters depending upon the material under test and, sometimes, it’s not suitable for testing very small components.

static hardness testing

Tabla de pino machihembrada con tratamiento autoclave indicada para hacer tejados, carpintería en general.

limitations of hardness test|hardness testing process